PCB Assembly, Printed Circuit Board Assembly in Taiwan

ISO 9001, 13485, 14001 Certified

Professional PCB Assembly & Prototyping Services

We provide rapid prototyping and mass production services for SMT printed circuit boards. We specialized in difficult and sophisticated PCB manufacturing.

Our professional team can communicate effectively with customer to fully understand their needs. Our competent and experienced engineering and manufacturing team help customers solve PCB manufacturing problems that could not solve in other EMS. We consistently achieve high quality and fast delivery. Therefore, we have won high trust and good reputation from our customers. Our customers say they can rest assured after handing over PCB production and assembly work to us. That is why many customers introduced new customers to us.

One Stop Full EMS Services

We provide turn-key material services for electronics, mechanics and box-build solutions to our customers. We work together with customer from new product development, prototypes, testing, sample run, NPI, to mass production. For box assembly, customer may choice to do CTO (Configure to Order) and/or BTO (Build to Order). We also support for After market maintenance and logistics Service.

PCB-Layout

We have very professional circuit board design companies working closely with us to provide customers with high-quality circuit board designs. They provide superior quality and competitive solutions.

PCB Fabrication

No single PCB manufacturer can meet all the requirements of every customers, which is why we have established close partnerships with more than a dozen different types of PCB manufacturers. Our selection is based on the different requirements of customers, such as time urgency, design complexity, size and cost, etc.

We have completed the quality certifications to all these vendors, so that our customers can have the most suitable Choice. We will properly propose the most suitable PCB manufacturing factory to customers。

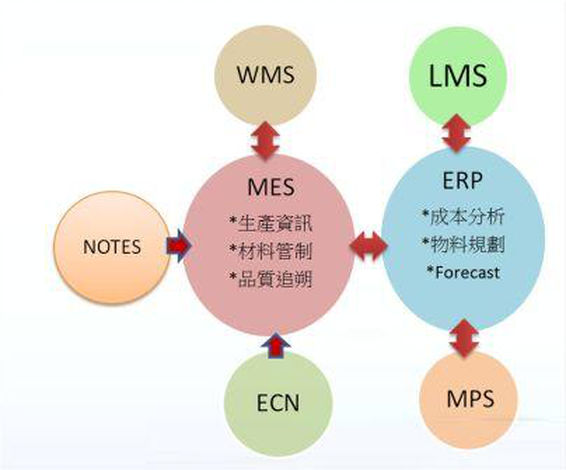

Turn-key Material & Supply Chain Management

We have rich experience in purchasing electronic components and mechanical parts, manage quality and cost of the materials, and also establishes good relationships with suppliers to achieve stable supply. Through supplier surveys, find reliable suppliers, clearly understand their quality systems and production processes, establish stable strategic relationships, and ensure that suppliers can continue to provide quality materials and conduct regular cost reviews. Suppliers are regularly audited. The audit items include past shipment quality, price, and delivery. Quality assurance engineering, timely replacement of suppliers or discussion of improvement measures based on the evaluation results, so as to meet the quality and price standards required by customers

SMT Assembly - PCB/SMT Manufacturing Process Flow

There are number of steps involved in the PCB assembly process depends upon the nature of the individual project. Below is the brief overview of general SMT manufacturing process:

PCB Assembly Capability

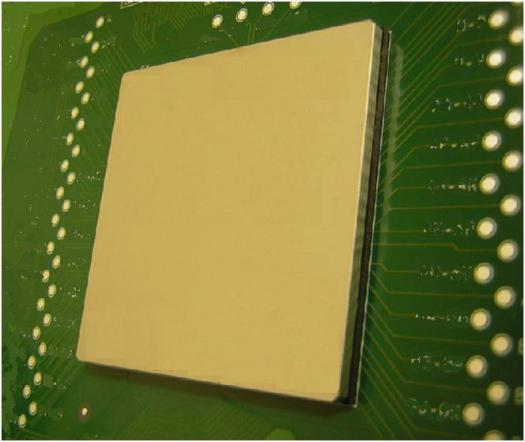

Our capabilities include assembly of BGA, uBGA, 01005, PoP (package on package) and lead-free assembly. We have completed a very challenging PoP (Package on Package) project t with a BGA pitch as low as 0.25 mm.

Lead Free PCB Assembly

We provide advanced lead-free PCB assembly manufacturing (lead-free) and RoHS-compliant circuit board components. We offer options for no-clean or water-cleaned fluxes.

Leaded PCB Assembly

Although most customers use lead-free processes, some customers must use traditional lead processes. Therefore, we still support PCB assembly using lead-based solder processes. We offer options for no-clean or water-cleaned fluxes.

Refer to the Reference Documents at the bottom of this page for the lead-free / RoHS-compliant assembly manufacturing guidelines.

BGA Rework/Reballing PCB repair Service

In order to assist customers to effectively reduce manufacturing costs and catchup development schedule, rework is a professional capability that the professional EMS factories must have. This will help engineer to modify their prototype and demonstracte product function for urgent situations

We have rich experience in BGA rework, including disassembly, soldering, and replacement of various planting balls (µBGA, PBGA, CBGA, TBGA, CSP, LGA); solder mask, pad repair, reflow, etc.

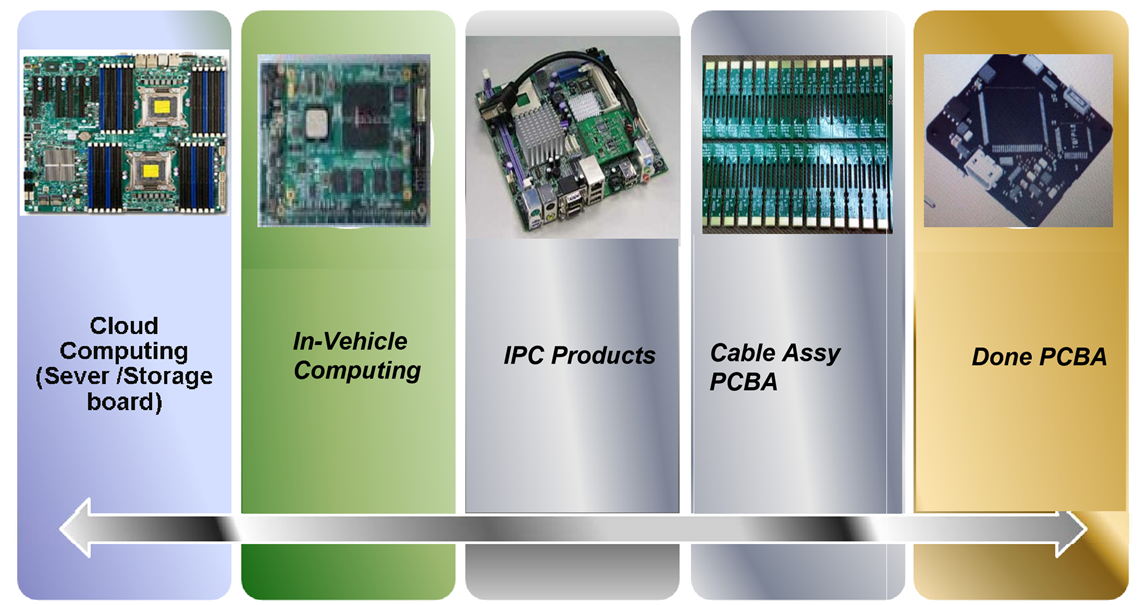

Example of our PCB Assembly Projects

High DEnsity BGA Assembly

Extremely Small Flex PCB

Extremely Large PCB

Example of Our PCBA Projects

PCB/SMT Assembly Equipments

- SMT/SMD placement equipment

- Screen printer

- Epoxy dispenser

- Reflow oven

- Wave soldering

- BGA rework station